In the food industry, the equipment combination of the chicken nugget coating production line is essential for the production of efficient and high-quality fried chicken nuggets. This article will introduce the core equipment in the chicken nugget coating line and their respective functions in detail.

First, the starting point of the chicken nugget coating line is usually the battering machine. The main function of the battering machine is to evenly coat the surface of the chicken nuggets with a layer of slurry. This layer of slurry not only helps the chicken nuggets to better adhere to the powder during the coating process, but also increases the taste and flavor of the chicken nuggets. The chicken nuggets after battering enter the next process. Clink this link to view more details about battering machine for chicken nugget coating production line.

Next is the coating machine, also known as the coating machine. The coating machine is a key equipment in the chicken nugget coating line. It delivers the chicken nuggets into the coating area through a conveyor belt. The coating machine is designed with a hopper and an adjustment device inside to control the amount of powder and the thickness of the coating layer. When the chicken nuggets pass through the coating area, the powder will evenly adhere to the surface of the chicken nuggets to form a crispy outer layer. The design of the coating machine makes it easy to operate, clean and maintain, and meets food safety standards.

After the coating machine, there is usually an air shower. The main function of the air shower is to remove excess powder from the surface of the chicken nuggets. Through the action of a strong fan, the powder attached to the surface of the chicken nuggets but not firmly coated will be blown off, ensuring that the final product has a neat appearance and a crispy taste.

After the coating is completed, the chicken nuggets will enter the fryer for frying. The fryer is another important equipment in the coated chicken nugget line. It controls the temperature and frying time of the frying oil to ensure that the chicken nuggets reach the ideal degree of doneness and taste. The fryer usually adopts the middle heating method to effectively alleviate the oxidation degree of the frying oil and extend the service life of the frying oil. At the same time, it ensures that the fried food will not be coked or carbonized, ensuring the health of the eater.

In addition, the coated chicken nugget line may also include other auxiliary equipment, such as quick freezers, forming machines, etc. The quick freezer is used to quickly freeze the coated chicken nuggets to maintain their shape and taste; the forming machine is used to process the chicken nuggets into a specific shape to improve the product’s appearance and market competitiveness.

In summary, the equipment in the chicken nugget coating line has its own unique role, working together to complete efficient and high-quality production tasks. The selection and use of chicken nugget equipment is of great significance to improving production efficiency, reducing costs and improving product quality.…

Read More

Conclusion

Conclusion

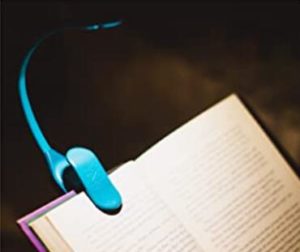

Do you love to read? If you’re an avid reader, and you prefer actual books, you’ll want to make sure you’re able to get the light you need when you sit down to read.

Do you love to read? If you’re an avid reader, and you prefer actual books, you’ll want to make sure you’re able to get the light you need when you sit down to read.  There are a lot of different lights available, and many of them are highly appealing. When you’re picking out a book light, you’ll be able to look at a lot of different options and find something that has the right look.

There are a lot of different lights available, and many of them are highly appealing. When you’re picking out a book light, you’ll be able to look at a lot of different options and find something that has the right look.